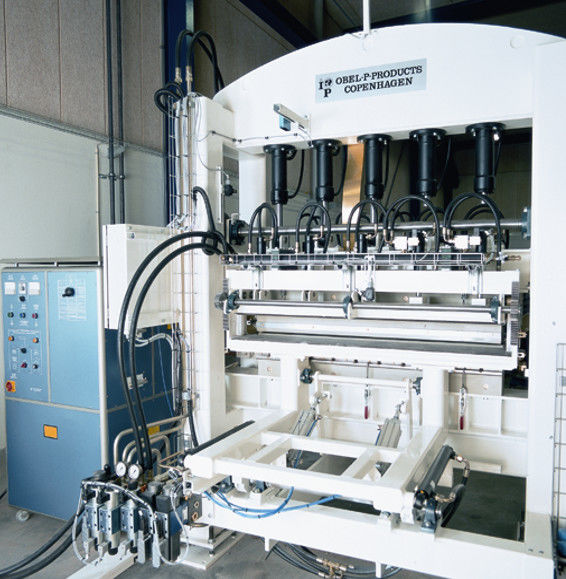

Presses

HF-Presses and Hot Presses

HF-Presses and Hot Presses

Since 1956 Obel-P has been producing High Frequency Generators and presses and we are today a worldwide leading supplier within this product range.

The program reaches from simply manual presses to fully automatic production lines. Many customer designed presses have been delivered.

Please contact us for any task you might have and we probably have the solution for you.

High Frequency Generators

- 40-200 kW output

- Aircooled

- Frequency 13,56 mHz

- Symetric output

- Fully automatic power control

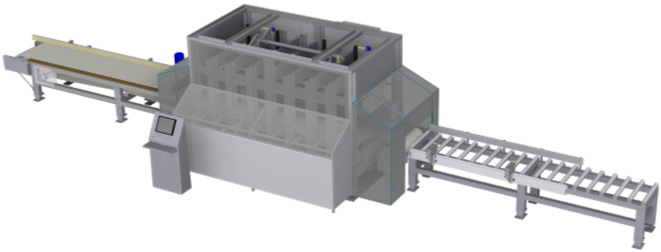

HF-Press type Economy

HF-Press type Economy

Presse platen:

- 3000x650x200 mm

Minimum workpiece length in the press:

- 2200 mm

The press can be delivered with fully automatic lay up unit.

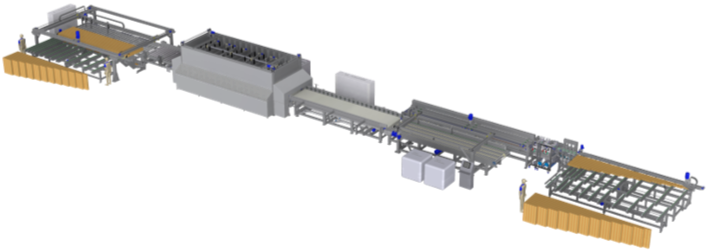

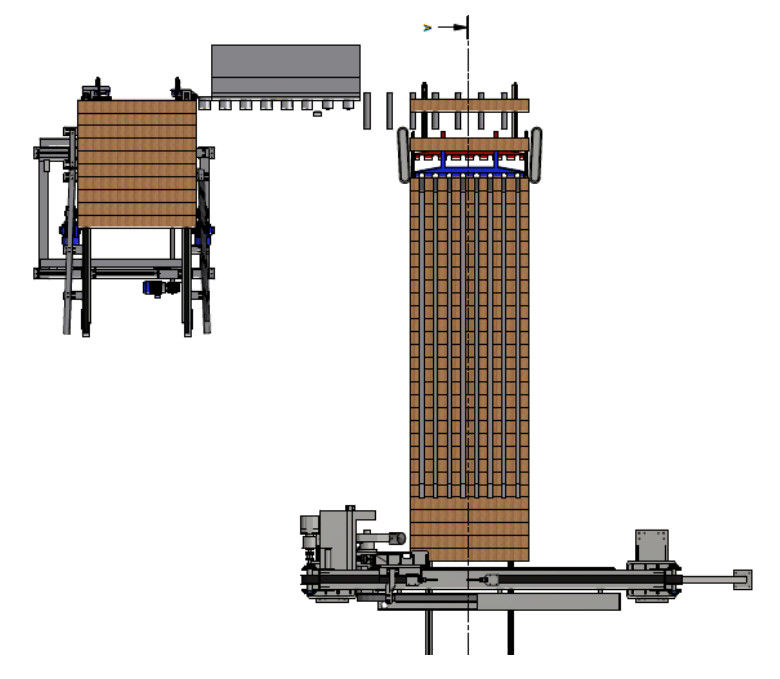

HF-Pressing line for window scantlings

- Press size 6250x1450x200 mm

- Work piece lenght 400-6100 mm

- HF-Output 160 kw

- Fully automatic lay up unit

- Glue application speed 300 Mtr./Min.

- Formate saw behind the press

- Manual quality control and stacking

- Capacity: 70 m3 pr. shift

Through feed HF-Press for window scantlings

- Speed up to 20 Mtr/Min.

- HF-Output 40 kW

- Glue: 2 Component MUF or UF

Automatic lay up units and stacking units can be supplied.

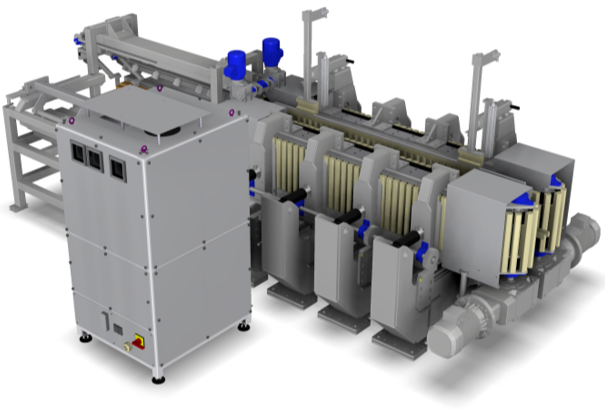

HF-Pressing lines for beams and CLT

- Press size 6500x1450x300 mm

- HF-Output up to 200 kW

- Lay up unit up to 24 mtr. length

- Glue speed 300 Mtr./Min.

- Closing speed 13 Sec.

- Output 100-150 m3 pr. shift

The presse can be equipped with a top pressue of 12 kg/cm 2 and can then be used for the production of CLT elements.

Hot melt composer for CLT

- For maximum lamella length 3500 mm.

- 45 lamellas pr. minute at a length of 3000mm.

- Complete with formate saw behind the press

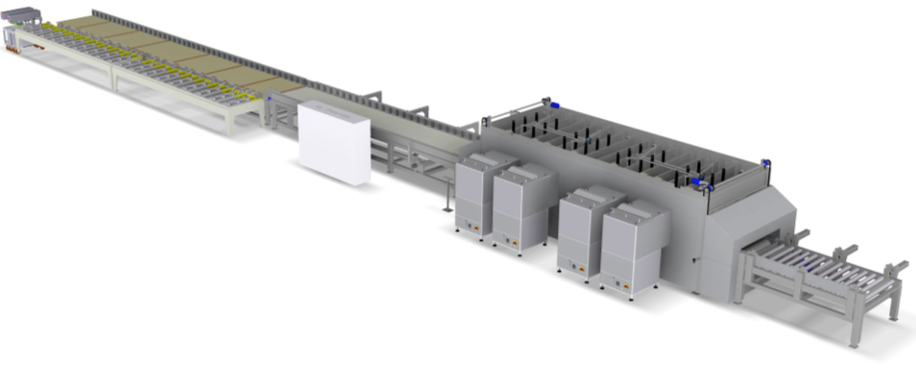

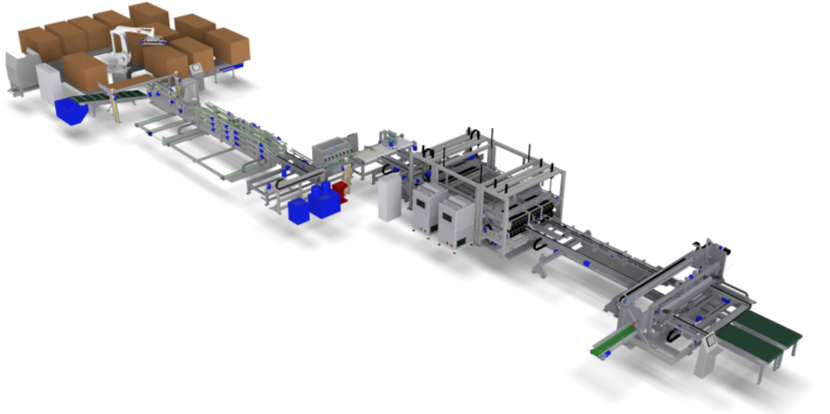

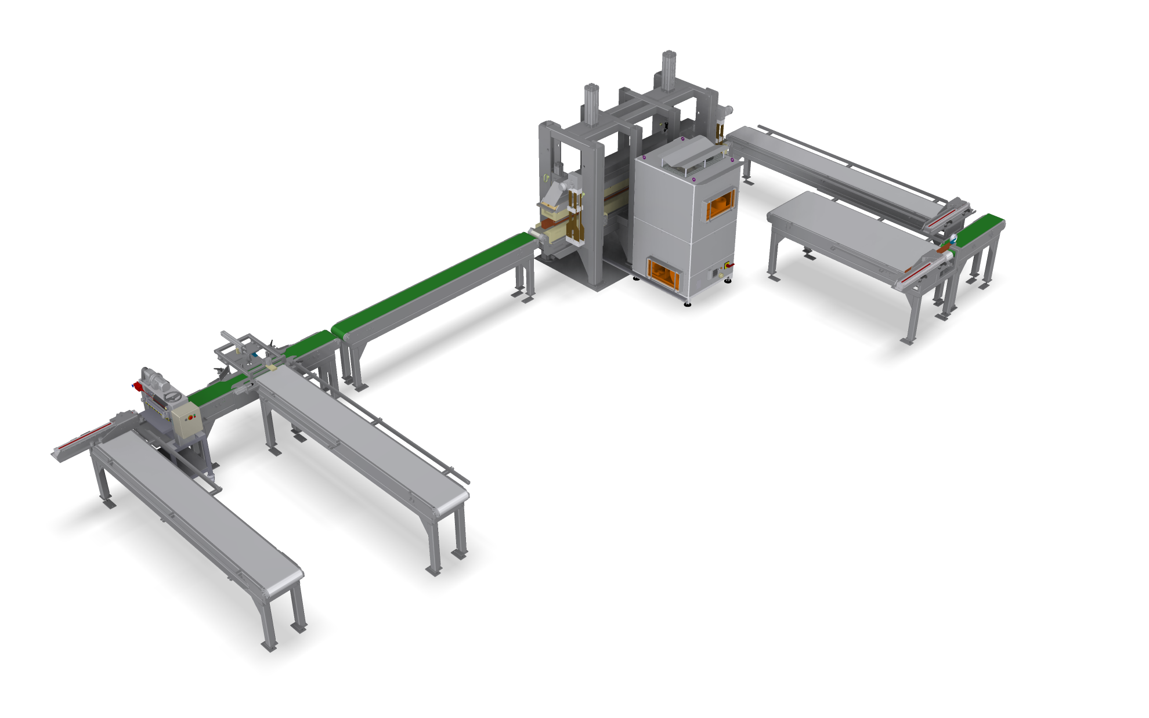

HF- through feed pressing line for glue boards

- Length of work pieces 400-2500 mm

- Fully automatic lay up unit for lamellas in 3 qualities.

- Glue application speed 300 Mtr/Min.

- Format saw behind the press.

- Automatic stacking can be delivered.

- Speed up to 6,5 Mtr/Min equal to 3500 m2/shift

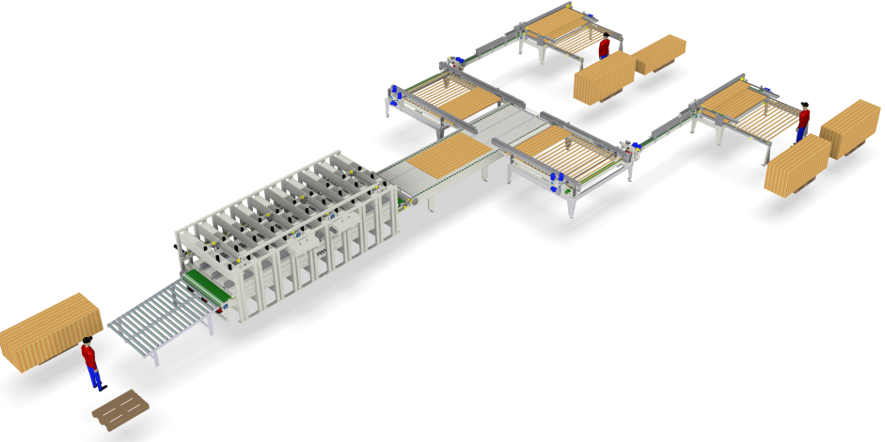

Hot pressing line for glue boards

- Press size 6250x1750x60 mm

- Heat medium: Hot Water

- Fully automatic lay up unit from 2 sides equal to 160 lamellas at a length of 800 mm.

- Presse line capacity 1900 m2 pr. shift.

- Fully automatic stacking can be supplied.

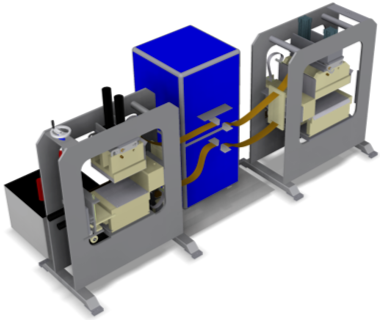

HF-laboratory presses

Obel-P supplies laboratory presses to institutes and glue suppliers.

The presses can be used for gluing of glue board, beams etc. as well as for heating of wood based materials or other components which contain moisture.

Of course the presses can also be used as a cold press and together with traditional electro platens as a hot press.

HF-Presse for armrests for chairs

- A special designed press for a Swedish customer.

- HF-Output 20 kW

- Glue application by roller

- Capacity 5 work pieces pr. minute

HF-Press for the production of wooden pencil slats

- A special designed press for Faber Castell.

- HF-Output 12 kW

- Glue application by glue nozzle.

- Capacity 60 slats pr. minute

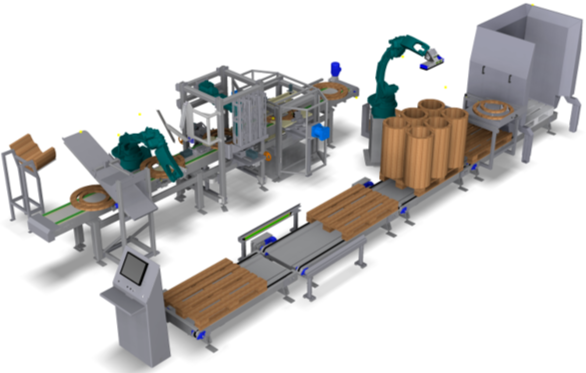

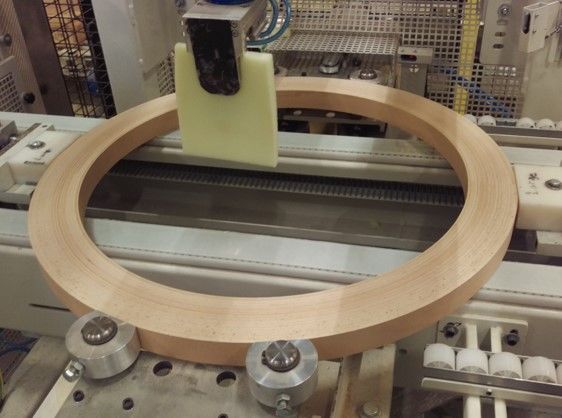

Fully automatic HF-pressing line for fingerjointed rings

A special designed press for a Norwegian customer producing the famous Stessless armchairs.

In this line we handle and cure the fingerjointed round chair legs.

Capacity 4 pieces pr. minute.

HF-Scarf Jointing press

Press for scarf jointing of plywood panels.

Length of board max. 3000 mm

HF-Press to produce Japanese posts

- HF-Press length 6000 mm

- 160 kw. HF Output

- Posts up to a length of 6000 mm

- Glue Recorzinol

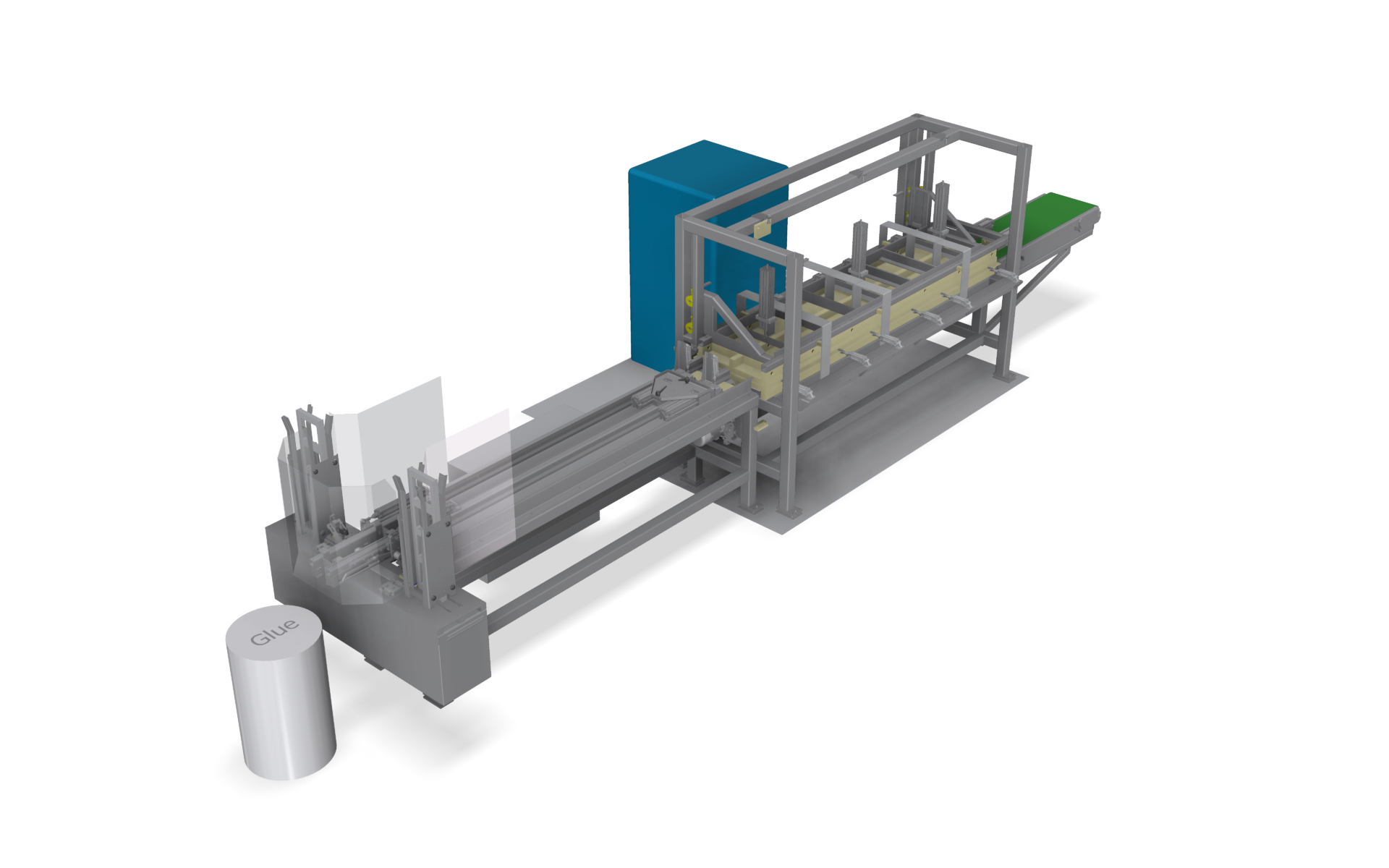

Pressing line to produce window scantlings

This line consists of the following:

- Automatic lamella feeder for 2 qualities

- Moulder

- Glue application for PVA c glue

- Automatic lay up unit

- Hot press

- Automatic stacking of the finished products